“Due to covid 19, extensive usage of plastic has become normal again; and it is a major setback for the eco business industry in India. Whilst on one hand, plastic serves as a protector for front line warriors in these hard times on the other hand plastics shouldn’t complicate the pandemic situation further. So, People should avoid single-use plastic wherever it is possible. The temporary setback for eco-friendly business doesn’t affect the scope in post covid times for green recovery of the planet” told the founder and CEO of Ecogreen unit S.K. Babu from Coimbatore.

The group of committed youths and eminent personalities of various fields are nourishing nature by finding solutions for social and environmental problems. At Ecogreen unit, community Based development program for income generating activities from waste to wealth concept for women groups, organic farming, ECO Tourism and rural upliftment are the main activities.

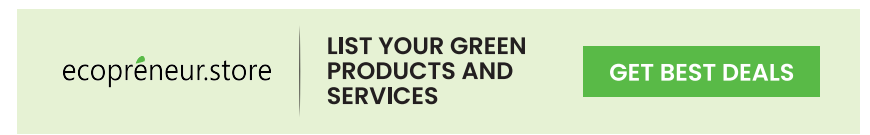

“About 5lakh hectares of banana cultivation only 10 percentage of fiber is extracted from banana wastage in India. And current manual fiber extraction methods need skilled labor but still fiber yielding is less while consuming more time. We at Ecogreen Unit developed a Banana fiber extracting machine which can be easily operated by cutting and inserting divided stem pieces into the machine to extract fiber” told Babu.

The fruit branches and leaves are contributing the major source of income for banana cultivation farmers besides leaves are used to serve food in India. The fruitful utilization of banana stems after harvesting is a biggest waste management problem for farmers too. In order to address such issues, Ecogreen unit developed machineries for value addition applications.

“We started a banana fiber extraction project in Sethumadi village in Coimbatore in TamilNadu. Our Bengaluru division developed a portable, 1HP and single-phase fiber extraction machine and this technology is introduced to self-help groups, farmers and entrepreneurs in overall 15000 people involved in this program across different states in India.”

Along with fiber extraction, Eco green unit offered training program for artisans on banana fiber crafts in Coimbatore cluster sponsored by Development Commissioner (Handicrafts), Ministry of Textiles, Govt of India. Banana fibers are extensively used as a blending material in the textiles industry. The international natural fiber market is promising for earning additional income for farmers while handling agricultural waste.

Light holder

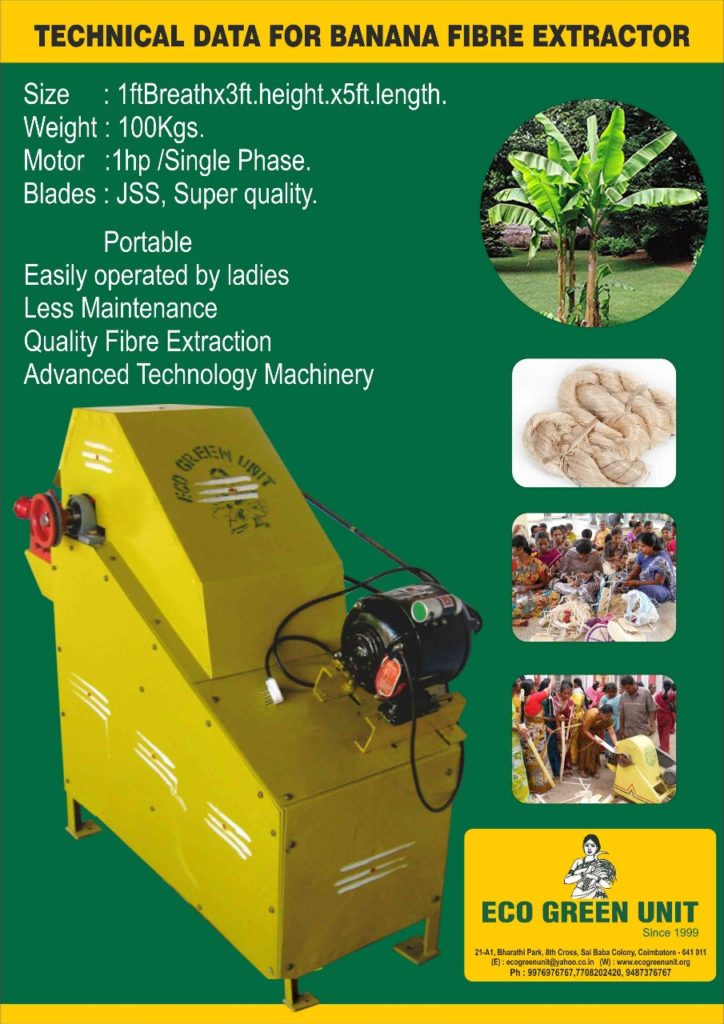

Saree made out of banana fiber

Handbag made out of banana fiber

Recently, DDO From Agricultural Department, Bihar initiated a Banana fiber Extraction and craft making Project in Bihar and Ecogreen unit is a co-partner for ongoing Mission in Bihar.

“Banana bark [After Harvest] is teared into sheaths and dried in the sunlight after then it is tied and kept in shade so that raw material lasts for 5 years without any damage. We have developed an easy and simplified unit, which consists of Slicing Machinery/Twisting machinery with 4 spindles. This Whole unit which gives an output of two-ply thread 5000mts/shift, consumes less power/Easily operated by women /Zero maintenance. The Dried banana bark sheath is used for twisting thread. The sheath is inserted in a calendering machine to straighten the dried sheath. Secondly the uniformed sheath is inserted in slicing machinery which is sliced according to the size of the thread. (0.3 mm or 0.5 mm and single ply or double ply). Next reeling process starts in a simple reeling device which is reeled in the cone. Finally, the thread will be twisted in the thread twister which consists of 1.5HP POWER [MOTORIZED]

Ecogreen unit offers solutions for coir value addition products as well. COIR WALA 2020 is a 5HP mobile extraction machine which can be taken into coconut farms and beneficial for small scale coir units, and automatic hydraulic coir pot machinery is used for biodegradable pot making for growing plants. They are into areca leaf plate manufacturing as well.

Coir pot machine

women training programs

“Eco friendly products cannot be compared with existing plastic or paper products in terms of price. We work hard to supply eco-friendly products for reasonable costs which has upcycling value for the planet and individual health. Moreover, the Entrepreneur who is into Eco Friendly projects should keep Quality, Quantity, In Right time in their mind to step into success platform”, he concluded.

The Ecogreen unit is doing their efforts to catalyze ecopreneurship ecosystem with appropriate technologies. Then what is your technology for green recovery?

Photo courtesy: Ecogreen unit

(Are you catalyzing green recovery with technology? will share your story together here)