Wind energy is one of the conventional and decades old renewable energy sources for India. Started in the early 1980s, Majority of the wind farms are located in the Class I wind sites( Turbines are designed for average wind speeds of 10 meters per second (m/s), or about 22.4 miles per hour (mph), and extreme wind gusts of 156 mph). A wind turbine is generally functional for 20-25 years. However, in India, in class I sites, wind turbines reached their life span and time for repowering.

A latest research by The Centre for Science and Environment titled Repowering Wind Farms: Maximizing energy yield from existing site layouts (2023), reveals that the wind farms in the Class I wind sites are already exhausted and are performing poorly. Hence, these wind farms need to be repowered.

Wind repowering is the process of replacing outdated wind turbines with modern and updated turbine technology. Wind repowering can bring various benefits to the wind farms in terms of efficient and effective utilization of wind energy, less noise pollution and safer for animals. Thus, it is important for the wind farms to be repowered.

Yet, there is a major issue that needs to be addressed after the wind repowering – managing the old turbines. Interestingly, a wind turbine’s 80-94% of materials are recyclable as it contains steel / iron, aluminium and copper.

However, wind turbine blades are an exception. They are made of fiber reinforced polymers (FRPs) which consist of polymers reinforced using glass fibers and carbon fibers. Thus, they are difficult to recycle. In spite of that, wind turbine blades are recycled using mechanical, thermal, and chemical methods. Using the method fibers are recovered from the epoxy-based composites waste.

Sadly, these methods are either costly, harmful to the environment, time consuming or degrade the fibre properties. Hence, wind turbine blades generally end up in the landfills, taking years to decompose.

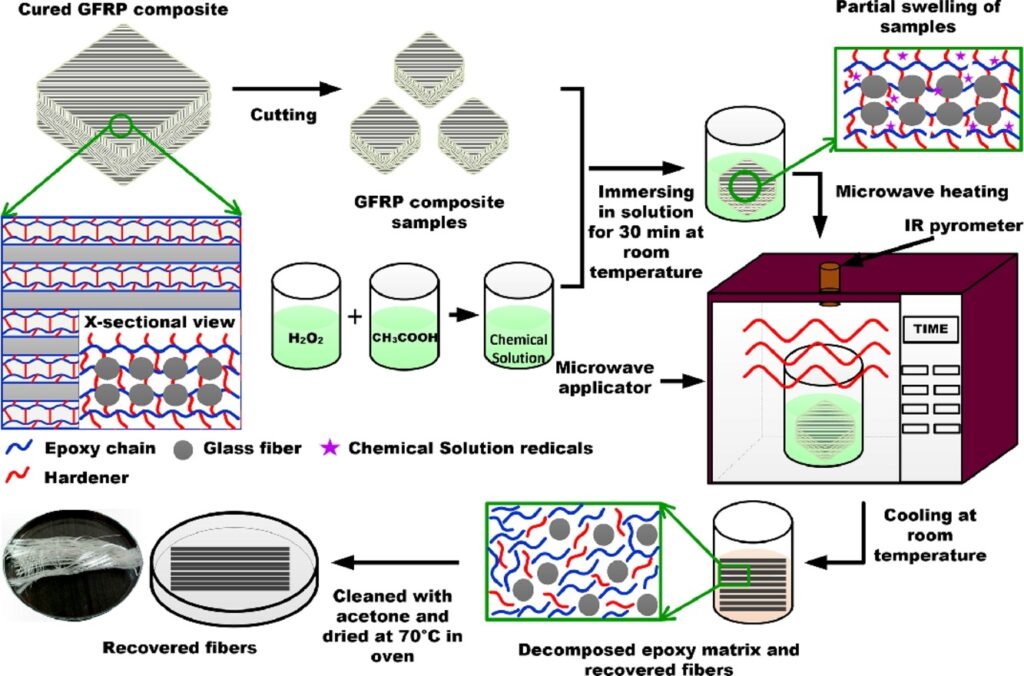

As a sustainable alternative, the researchers at IIT Mandi has developed a low-cost microwave-assisted chemical recycling process to recycle Glass Fiber Reinforced Polymer (GFRP) composite waste.

In the MACR process, researchers use green solvents such as hydrogen peroxide and acetic acid to decompose the GFRP composites. Moreover, microwave heating is applied owing to its characteristics like rapid, volumetric, and uniform heating phenomena.

The research was led by Dr. Sunny Zafar, assistant professor at School of Mechanical and Materials Engineering along with Dr. Venkata Krishnan, associate professor, School of Chemical Sciences and their students Manjeet Rani and Priyanka Choudhary.

The researchers explain the recycling process: “during the microwave exposure, the solution(hydrogen peroxide and acetic acid) provides an oxidation medium, which enhances the decomposition of the epoxy matrix material of composite. After which, the process depolymerise the epoxy matrix surrounding the glass fibers and hence the glass fibers can be recovered/recycled.”

During the process vapors from the green chemicals will emit. However, the investigators are yet to identify the by-product vapors produced in MACR using a gas chromatography analysis.

Interestingly, this process is not limited to glass fibre recovery only. The researchers said that the MACR can be used to recycle carbon fibre from carbon fibre based composites also.

During the research, researchers came across two major challenges. Developing a green and environmentally benign solution that can effectively depolymerise the epoxy thermoset matrix. Another challenge was optimizing the microwave exposure parameters. This includes estimating the reaction time and temperature to minimize the damage on the physical and mechanical properties of recycled glass fibres.

As a future prospect, the team is looking for collaboration with potential companies in India to scale the MACR technology for GFRP and carbon-fibre-reinforced polymers (CFRP) for the decommissioned wind turbine blades.

The team said:“ Recycling of GFRP/CFRP is in a very nascent stage in India. More emphasis needs to be placed to create awareness in terms of processes used to recycle GFRP/CFRP. Also, there is a strong need to develop sustainable processes to recycle GFRP/CFRP.”

Share your green story!!!

For more information: https://pib.gov.in/

Featured Photo: George Shervashidze via Pexels