According to the Food Waste Index Report 2021, “An estimated 8-10 percent of global greenhouse gas emissions are associated with food that is not consumed. By throwing away 17 percent of food available at retail, food service and consumer level, the impacts of food systems on climate, nature and pollution are generated needlessly”.

In India, methane emissions from landfills are ranked second, next only to coal mining. Methane is a short-lived climate pollutant (SLCP) that needs to be mitigated. This is because it contributes to the formation of ground-level ozone which is a dangerous air pollutant.

Food wastage comes with an ecological footprint. Of course, reducing food wastage is one ideal solution, however effectively managing the waste for improving public health, safety and cutting down GHG emissions for renewable energy benefits is another feasible model to implement.

“For my M.tech project, I developed a plug flow digester. Later, I worked for a few years in the industry. During that tenure, I made a small digester for my home purpose. This brought more enquiries from friends and family members to install the digester in their houses. And this is how we started Vivesty Green”, co-founders, Anuprasad SG and Vignesh KR.

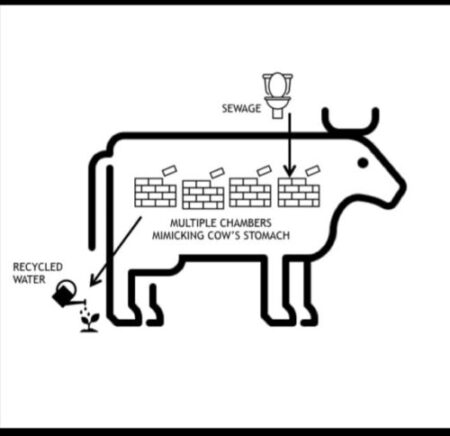

Vivesty Green manufactures portable and fixed dome, plug n play and LDPE biogas plants. Vivesty is not devoid of any challenges. Anuprasad says- “In a 0.5 m3 biogas plant,2 kgs of food waste per day should be disposed. However, after installation, we came to know about something interesting”.

Anuprasad says, “People are disposing higher quantities of food waste in this small biogas plant. They didn’t bother about the quantity of waste. They just wanted to dispose of the waste. As a result, foul smell used to come from the digester due to less bacterial count. So we stopped manufacturing smaller digesters and started selling 1 m3 or 1.5 m3 which can handle 8 kg to 15 kg/day”.

After the food is digested in the biodigester, liquid slurry and biogas are the two by-products produced. The liquid slurry is rich in nitrogen, phosphorus and potassium and it is useful for farming. The digester is attached with a soak pit. So, if any excess liquid is formed it will go to the ground which doesn’t contain any harmful substances. The biogas is used as a fuel to light the stove. This means one can save 50% from LPG.

Anuprasad wishes that while building a new house just like toilets, food waste management devices should be included. In addition to that, government subsidies should be included for biogas plants. The cost of fibre reinforced polymers got higher. Thus we started making alternative raw materials like LDPE membrane for biogas and nylon membrane for toilets. Reducing the existing GST slab for biogas will be a great relief for the manufacturer to make them affordable for farmers and rural communities. Vivesty Green is eyeing the African market and aims to install 100 bio digesters by the end of next financial year. A local manufacturing unit is another plan for Vivesty Green.

Do you have an innovation for clean cooking fuel?

Share your Green Story!