(Author: Akhilesh)

According to the National Green Tribunal (NGT), 60% of the sewage generated by urban India enters into water bodies like rivers as untreated and it causes serious damage to air, water and earth. As per World Bank, the urban population in India grew from 28.34% in 2011 to 34% by 2017. With the growing urbanization, the sewage related problems are also growing in India.

The Central Pollution Control Board (CPCB) report estimated that the sewage generation in India is around 72,368 MLD with operationalised sewage treatment capacity of 26,869 MLD; so there is a huge gap between sewage generation and treatment. This untreated sewage mixes in the environment and leads to its degradation. Infact, in 2018, CPCB identified that there are 351 polluted river stretches in India. In CPCB assessment, 31 states and Union Territories (UT’s) did not meet the water quality criteria.

A team of people realized the magnitude of the problem, and took initiative for sustainable solutions. ECOSTP, a Bangalore based startup, developed a unique technology to treat sewage waste with a mission to reclaim every drop of waste water naturally. In the view of the ECOSTP team, maintaining conventional motor based Sewage Treatment Plants (STPs) is expensive and an additional pressure on nature since it is noisy, needs electricity, and it requires skilled operators for day to day maintenance.

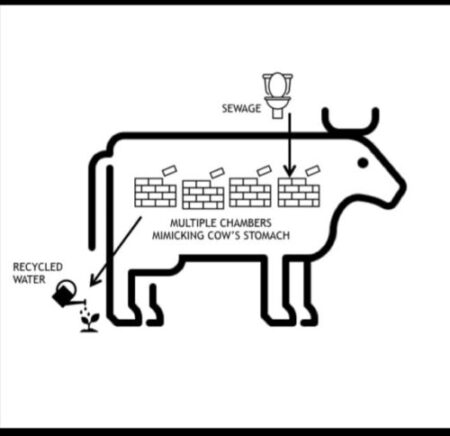

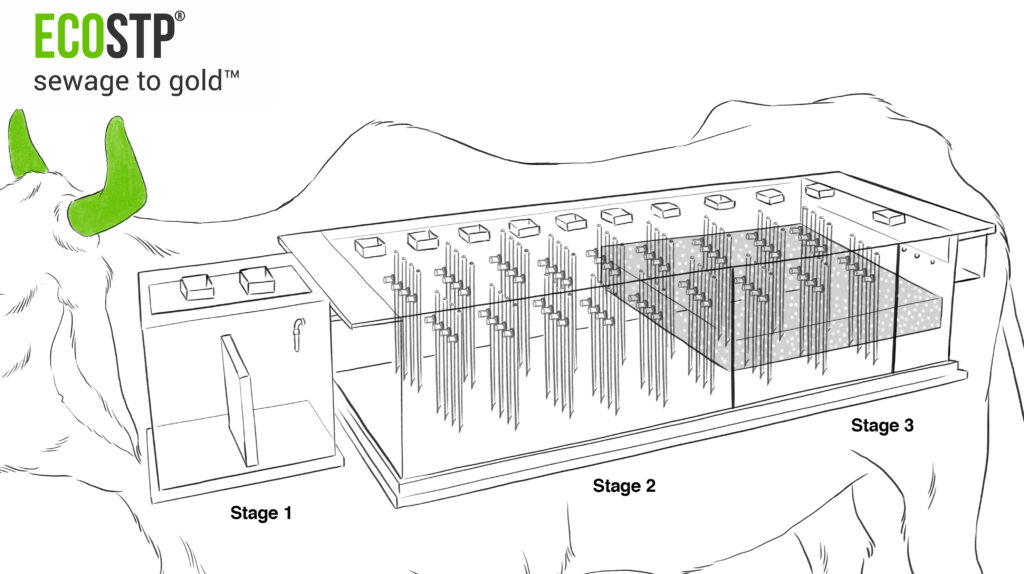

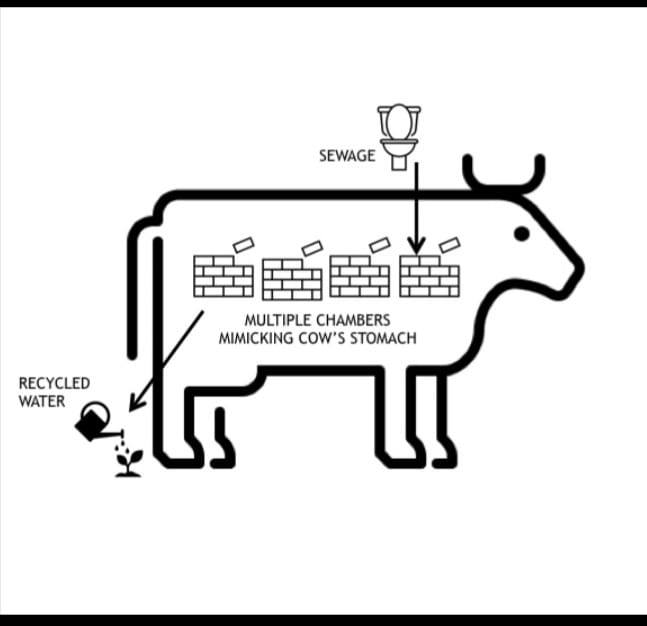

According to the development team, the ECOSTP sewage treatment plant is a replica of a cow stomach. Like a cow stomach this sewage treatment plant has different stages to treat sewage waste with the help of anaerobic bacteria. Old septic tanks also work based on anaerobic bacteria, however the key difference is that the digestion process is accelerated by using a cow stomach model.

“In the first step, which is called as a Rumen Digester Filter stage one, the sewage waste is collected in a large tank sealed shut after adding the anaerobic bacteria from dung; This micro-organism breaks down the waste and the solid part of the sewage sinks to the bottom and the rest of the waste flows to the next chamber”.

“Once the waste flows to the second chamber, stage two of the Rumen Digester Filter starts with a mix of more anaerobic bacteria. In stage three of the third chamber, the sewage passes through gravel and bacteria for further cleaning”.

“The last stage of ECOSTP is called the gravel filter stage where remaining solids and nutrients are removed by gravel filters planted with wetland plants. According to the team the treatment is completed after the fourth stage, however, they recommend using disinfectants to ensure water safety further.

It uses zero power and zero chemical in sewage treatment; and has no moving parts like conventional STPs which use energy, hogging motors, exhaust fans, pumps and blowers.

Of course, their journey is not a smooth one. Tharun kumar recollected his memory of how hard they fought to get their first client. In their experiences, sometimes convincing the clients is also hard with features like the system that doesn’t require any electricity and environmentally friendly sewage treatment. Though it is challenging, they still continued their journey for a greater purpose.

“MD of Coevolve Estates Suhail Rahman was our first commercial client. We had done solid pilots and ground work before we met him and his team was convinced of our technology. I remember the negotiation my colleague Praseed and I did with Suhail. The key factor which swung the decision was because we insisted on a 50% advance which was unheard of in the real estate industry!! Looking back we would have lost the deal if we had agreed to a lower amount – as this demonstrated our confidence in the product. Soon after that Suhail gave us a YouTube interview on why he chose us”

At present, ECOSTP has around 100 clients in 17 states of India. Team proudly says that they have treated 530 ML of sewage waste, saved 920 MWH of electricity and 950 tons of coal since the inception. ECOSTP technology was discussed in 8th world water forum Brasilia, 2018; and selected as a best practice case study for United Nations Sustainability Asia Pac report. Also they are part of some mentorship programmes of prestigious international institutions and organizations in different countries.

However, as per the team, ECOSTP technology also has certain challenges like space requirements for different chambers and pipes. Getting such spaces particularly in metropolitan cities is not that easy. So, they came up with a model where all sewage chambers are built beneath the buildings or roads. The final plant and gravel filter stage of the process is built in open spaces like gardens.

At the policy level, the ECOSTP team thinks that the government should accept the fact that the citizens are unable to run existing complex STP’s. Therefore, the Government should encourage natural sewage treatment technologies by extending subsidies in a similar way to solar and rain water harvesting practices.

ECOSTP is one of the finest examples for exploring nature to find solutions to address contemporary environmental problems.

website: http://www.ecostp.com/