(Author: Joseph Fernandez)

It is a little known fact that when NASA launched its Space Shuttle Discovery into space in 2012, a secret of its strength to withstand the tremendous heat generated on re-entry into the Earth’s atmosphere was over 27,000 ceramic tiles that make up its outer skin.

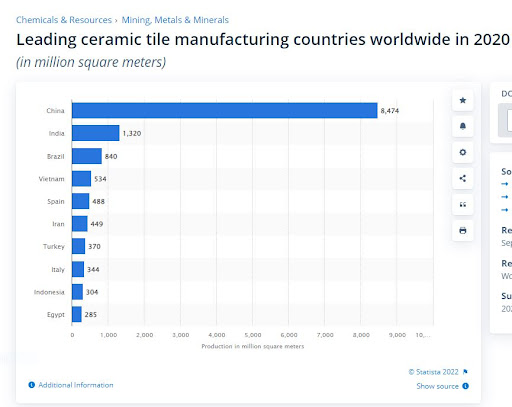

On Planet Earth below, Ceramic is one of our most used building materials, produced mostly by countries of the Global South. Essentially made of clay, Ceramic is one of the hard, tough, durable and corrosion-resistant products on the planet. The world’s top 4 ceramic manufacturers—China, India, Brazil and Vietnam— produced 11, 168 million square meters as recently as 2020. The 2018 Revision of World Urbanization Prospects , UN reported, 68 percent of the total world population is projected live in urban areas by 2050. Rapid urbanization is putting gigantic road blocks for sustainable infrastructure push for urban dwellers in developing countries.

Ceramic is a source material for tiles and sanitary wares for infrastructure use in the global housing boom around the world. The “Ceramics Market Size, Share & Trends Analysis Report By Product (Traditional, Advanced), By Application (Sanitary Ware, Abrasives, Tiles), By End-Use; By Region, And Segment Forecasts, 2019 – 2025” reported that global ceramic market is expected to grow with a compound annual growth rate of 8.6 percent from 2019 to 2025.

The global production of ceramic waste powder (CWP), which is produced during the final polishing process of ceramic tiles, exceeds 22 billion tons. As the market is attractive, the industrial ceramic rejects and used ceramics are ending with landfills. The disposal of CWP in landfills causes significant environmental problems (i.e., soil, air, and groundwater pollution).

Meet Shashank Nimkar, founder of Earth Tatva. To address the ceramic waste management challenges, Shashank started Earth Tatva with a global mission to upcycle ceramic products to make beautiful, functional and decorative products. Shashank is a multi-award winner cross-disciplinary designer who enjoys working with materials and developing solutions that add value to our society. He innovated TatvaMix as a part of his graduation project for his Master’s programme at National Institute of Design, Ahmedabad, India.

Using this recycled material he aims to turn the linear ceramic production into a circular process. So that the industry & studios can collectively reduce the carbon footprint while continuing to make high aesthetic and functional ceramic wares.

Shashank says: “When I was pursuing a master’s programme in industrial design, as a part of an industrial visit, our batch visited a ceramic manufacturing cluster. There, I saw heaps of production rejects thrown outside the factories. Today, ceramic industries are facing daunting challenges in the form of production waste. Hence, when I had to take up a project for the master’s programme, I decided to work on a self-initiated project to find ways to utilize loads of fired ceramic rejects at industries rather than taking up a traditional internship”.

“As a designer, I did not want to make just another – my own version- of an existing product, I was more interested in making a universal recycled material that would be objectively meaningful for everyone, which everyone can use to make beautiful, functional and decorative products”.

The core innovation of Earth Tatva is that they have developed a universal recycled ceramic material called ‘TatvaMix’. TatvaMix has been tested and reported to be 35% stronger than traditional ceramics. They are planning to offer TatvaMix to ceramic manufacturers so they can make high quality recycled ceramic products for their clients across the locations. Henceforth, it will reduce the mining of natural resources by 60% with lower energy consumption.

Clay is a natural material and it is challenging to work while considering its natural tendency of inconsistency and unpredictability. With constant material composition testing and optimizing processes, we are able to sail further ahead to bring high quality recycled ceramic products for consumers at affordable rates.

Putting things together at the studio to get a consistent production outcome is something we are working towards. At present, Earth Tatva have launched mugs and salad/serving bowls and will expand the product range further as we move ahead. In any ceramic manufacturing process, most of the energy consumption happens during the firing process. Most industries in the conventional firing process use CNG as fuel because it is cleaner than the previously used fossil fuels.

In the recycling process, one challenge is during the pulverizing of waste. Being a fine particle it is important that people working at the facility should wear appropriate gear so they do not inhale these particles. Otherwise, the product manufacturing process from recycled ceramic is similar to conventional process, except our recycled material matures at 20 °C to 100 °C lower temperature than current industry standards, hence, generating lower emissions.

Shashank observes that Logistics is a common challenge for any recycling industry. The current surge in fuel prices has increased the transportation expenses for every industry and if a policy could support the freight expenses of waste then the overall recycling process may become economical than what it is today.

He concludes with these thoughts: “Consumers are better aware about the impact of their choices and consciously exploring the options with lowering footprint on the environment. This is encouraging for everyone who is working on relevant innovations. India’s youth is actively taking initiative to work towards innovation and are more open to ideas, change and discussions. With high tolerance they are more willing to accept and promote a climate solution, whether in the form of a product or a service. This is a huge positive indicator for the Indian circular economy market and our positive contribution towards climate action”,.

At 46000 feet above the earth’s surface, the Space Shuttle Discovery proved the effectiveness of ceramic. On our blue planet, Earth Tatva is betting on the upcycling industry for green recovery while minimizing nature resource usage and lowering energy consumption to make ceramic products.

What is your strategy for our green recovery as a planet?

Share your green story!

Sources:

https://www.earthtatva.com/

https://www.sciencelearn.org.nz/resources/1769-what-are-ceramics

https://www.statista.com/statistics/939329/global-leading-ceramic-tile-manufacturing-countries/

https://www.intechopen.com/chapters/64275

https://en.wikipedia.org/wiki/Space_Shuttle

—Joseph Fernandez

Joseph Fernandez is an author and communications leader who helps create solutions that deliver transformative results for communities, organizations and nation states across our world. He is the author of 25 books including

Corporate Communications: A 21st Century Primer (Sage Publications, 2004). For more information on his work, visit his website: www.joseph-fernandez.com