A white paper titled Plastics, the Circular Economy and Global Trade by the World Economic Forum reported that more than 400 million tonnes of plastics are produced every year. Despite such production, on a global average only 14–18% of plastic waste is formally recycled. It is posing a threat to the goals of sustainable development. The best way to tackle plastic waste is either to avoid it or upcycle it. There are many alternatives taking shape to avoid plastic in all possible ways.

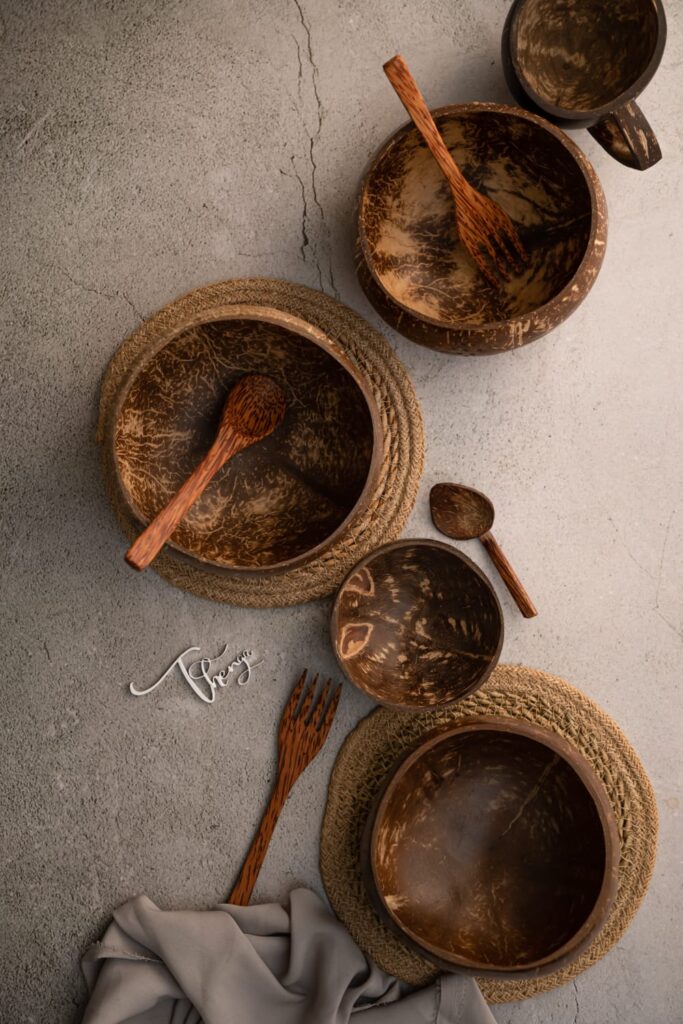

Thenga is one of such organizations working towards eco-friendly alternatives by using coconut shells for kitchen utilities and decorative products.

“I have a keen interest towards natural and eco-friendly products. I wanted to create products that are beneficial for the environment and useful for the people. In addition to that, I want to become an entrepreneur. This combined passion led to the formation of Thenga” told Maria while sharing her motivation behind starting Thenga.

Thenga has 28 different types of products manufactured using coconut shells. Different kinds of bowls, tea cups, planters, candles and mobile stands in different shapes and sizes by using coconut shells.

Maria says, “The process is completely natural. We don’t apply with any sorts of chemical treatment during the entire manufacturing process of our products. However, the good finishing of the product is possible because of the machine buffing. As we are only using coconut oil, the finish can fade or look dull after 20 wash. However, customers can replenish the product with coconut oil. People are happy with the pricing of the products as products stay for life time”.

Maria was in Mumbai for a long time for studies and work. Maria is so passionate about creating value-added products out of coconut. Her initial options were coconut water, coir, husk and shell. However, after rigorous research, she opted for the coconut shell and returned to kerala.

A lot of efforts are required for choosing the best coconut shells for products. Right size and shape is the key to an excellent product. As there is no standard size that can go through the machine, all the product has to be hand carved. All this plays a role in determining the price of the product.

Natural products manufacturing comes up with its own challenges. For Thenga, the raw material-the coconut shells, its sizes and shapes posed a problem as it comes from nature. For instance, if they mention a bowl is 500 ml or cup is 200 ml, that is difficult, however they need to bring standardization for the market. So, Thenga had to have a strong system for filtering the coconut shell based on size and shape.

As per the Thenga’s experiences, currently they don’t find challenges in manufacturing. Talking about the market, Maria sees more active customers from the USA and Europe. They are consumers who understand the value of natural products. However, educating and convincing the customer about the slight difference in the shape and size of the product was a hurdle in initial days. India is yet to evolve in the market for natural products.

“I wish the process, facilities and procedure should be a bit more streamlined and support in buying machinery is beneficial. If the government can mandate choosing eco-friendly products, it would create more demands for eco-friendly products. This would help small manufacturers in eco-friendly products”.

Thenga turned 80,000 shells from going into landfills to beautiful housing utilities and decorative products. Else, these coconut shells could be a breeding ground to mosquitoes. And, no additional resource is extracted specifically for their products. For instance we have to cut trees to make wooden furniture. Instead, we have upcycled the shell which goes into waste.

What is your strategy for our green recovery as a planet?

Share your green story!