Ajinkya Dhariya and Aasawari Kane came across two different issues. One saw a sanitation worker manually segregating sanitary napkins using bare hands. Another, experienced air pollution from an incinerator for sanitary napkins. These issues motivated them to bring a better solution for a key issue – menstrual waste management.

Menstrual waste management is a serious issue that is to be addressed across the globe. According to the Department of Drinking Water and Sanitation, “menstrual waste refers to blood, bodily tissues, and used menstrual absorbents, including cloth, disposable sanitary napkins and other materials used to capture or absorb blood during menstruation.” The report adds that 12 billion pads are generated as menstrual waste every year. Sadly, these wastes are treated in an unscientific way by being burnt in the open, buried or disposed of in the open, etc.

With a growing population, the need for safe access to menstrual hygiene devices and disposal of these devices is a must. Started by Ajinkya and Aasawari, PadCare Lab is on a mission to address these issues.

Founders says- “Every sanitary napkin ever manufactured on earth is still on earth. Components like plastic and super absorbent polymer makes the pad non-degradable. Unfortunately a limited percentage of menstrual waste goes to incineration. Thereafter it is directly converted to ash and ends its life-cycle.”

However, PadCare Labs wants to complete the loop of menstrual hygiene economy by generating harmless and recyclable output out of sanitary pads. PadCare Labs achieves this goal by offering three different products.

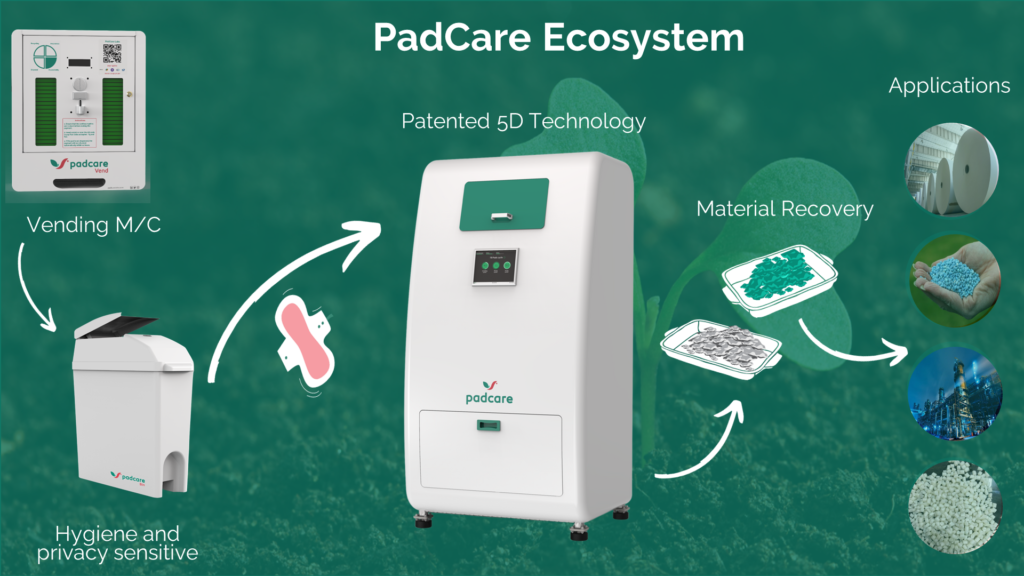

PadCare Vends is a sanitary napkin dispensing machine. The machine can be operated using the QR/RFID/Coin system. One can customise the payment option, which is an advantage of this machine.

Second, the PadCare bin which comes along with a PadCare Vap. This is a secured collection bin which can store 75 pads for up to 4 weeks. This bin can store used pads without any bacterial contamination or odor in the washroom.

Next, is a device developed by PadCare for disposal and recycling of used sanitary napkins. The recycling device works on our patented 5D technology. The 5Ds are Disinfection, Decolorization, Deodorization, Disintegration and Deactivation of Superabsorbent polymers(SAP).

Ajinkya and Aasawari explain the recycling process: “First, the pads from Padcare bins are collected and brought to the nearby PadCare facility. Then, they are processed to make them fit for recycling. After that, using the device developed by us, the pads are recycled. This process is called chemo-mechanical process. After the process, two byproducts are obtained – a segregated, disinfected cellulose and plastic.”

Cellulose is used in the packaging industry and chemical industry. The cellulose is used as a raw material for various chemicals, paper & pulp industry, décor products and insulation industries. Paver blocks, table tops, plastic pellets and composite material applications can be made from the plastic.

The PadCare machine can recycle biodegradable pads and tampons as well. The company is also planning to innovate solutions for diaper disposal and recycling. Owing to the fact that there is no alternative for it as well as it too takes 800 years to degrade.

In the entrepreneurial journey, PadCare faced many challenges. They faced difficulty in gathering data for research and development. This is because they were developing user-centric products which have a lot of taboo. After that, they faced hurdles in people accepting recycled materials. Thus, they diversified into tertiary applications like paver blocks, table tops, packaging material etc, which were readily acceptable.

“People are slowly switching to sustainable menstrual products. However, switching to a completely new product like a menstrual cup will take time. This requires immense behavioral change which takes a long time. Some of our beneficiaries are more comfortable using a sanitary pad than switching to a new product like a menstrual cup. In such cases, providing them solutions that are sustainable is a must”.

PadCare Labs is currently processing 100 Kg of pads per day. From the processed pads, they make recycled cellulose and plastic material. Thereby reduce carbon emissions. Team PadCare wishes for comprehensive policies and regulations. They believe that better initiatives and well defined policies will speed up the implementation of innovative solutions.

Do you have any innovation for menstrual waste management?